Factory Price For Spring Roll Production Line - Clipped Sausage Production Line – Ainister

Factory Price For Spring Roll Production Line - Clipped Sausage Production Line – Ainister Detail:

The clipper machine can be used for different series of products, sausage, ham, salami, polony, also for butter, cheese and others. Because of its wide variety, easy storage, convenience, and practicality, people always love meat products. Generally, clipped sausages are mostly made of plastic casings, which have good airtightness, easy storage, and strong toughness.

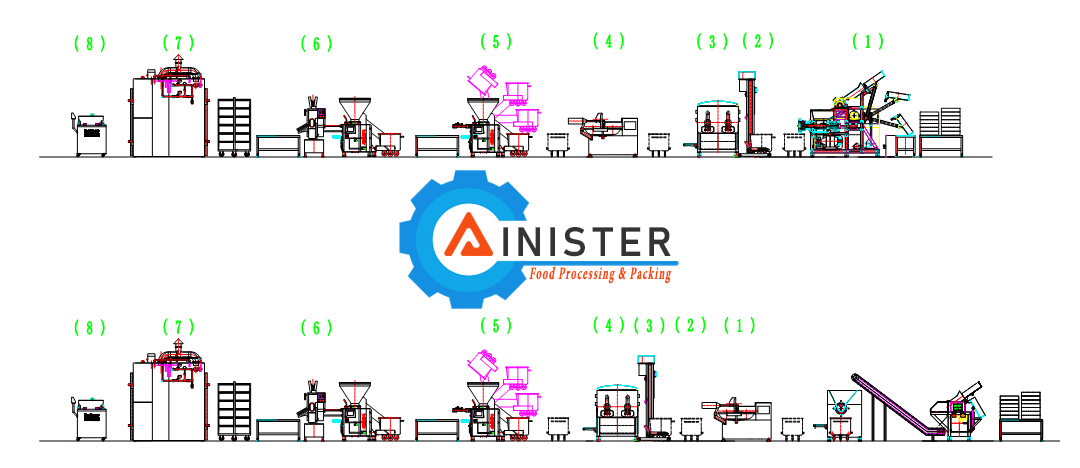

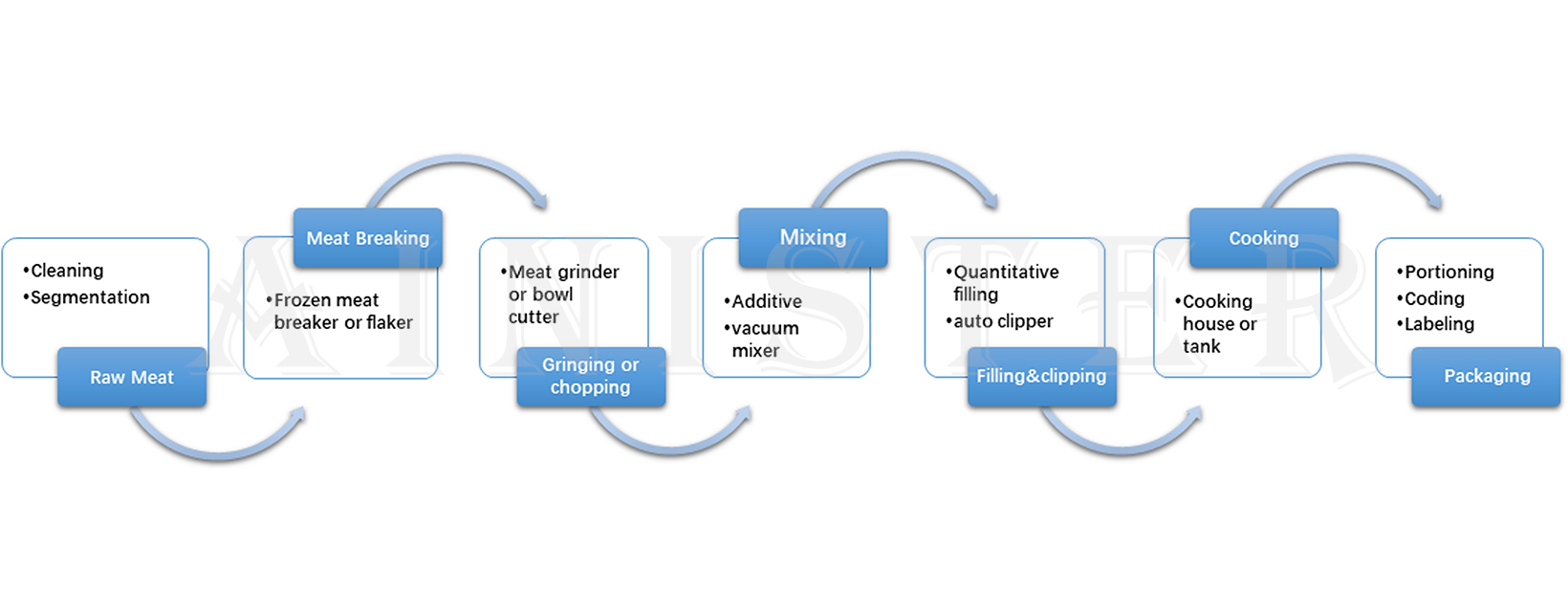

The main structure of the full set of equipment is made of high-quality 304 stainless steel, with high processing accuracy and meeting food safety requirements. The appearance is delicate and easy to clean. For the raw meat processing steps, the large-volume meat can be ground directly to shape, or it can be initially broken into small pieces, and then processed step by step.The equipment structure is reasonable, easy to disassemble and wash, and easy to replace the wearing parts. At the same time, it can be customized according to different process requirements.

The raw material processing equipment includes frozen meat breakers, meat grinders, choppers, mixers, etc, which are essential equipment for meat processing.The equipment are suitable for different types of frozen meat, fresh meat, vegetables, and various additives. It can be processed into different specifications, the materials are mixed evenly, working with the vacuum filling machine series, improve the production efficiency and product quality.

The core equipment of clipped sausage is the clipping sealing machine.According to different product types, choose different models and clip sizes.The automatic clipper machine adopts a servo control system, touch screen operation, accurate positioning, adjustable speed, and can be matched with different brands of filling machines. Choose different clips and models according to different products. Meet the requirements of all kinds of sausage products.

The automatic clipper series is suitable for different types and models of clips. U-shaped, aluminum wire, etc. The speed is fast and the product shape is beautiful. we also supply different casings, dozens of varieties of multi-layer co-extruded film nylon casing, smokable sausage casings, and shrink barrier skin pouches/films for cooked meat products.

Specification and Technical Parameter

Compressed Air:0.06 Mpa

Steam Pressure:0.06-0.08 Mpa

Power: 3~380V/220V Or Customized according to different voltages.

Production Capacity:100kg-2000kg per hour.

Applicable Products: Salami, Sausage ham, Snack sausage, clipped sausage, etc.

Warranty Period: One year

Quality Certification: ISO9001, CE, UL

Product detail pictures:

Related Product Guide:

With our excellent administration, strong technical capability and strict excellent control method, we carry on to offer our clients with responsible good quality, reasonable costs and great companies. We intention at becoming considered one of your most responsible partners and earning your pleasure for Factory Price For Spring Roll Production Line - Clipped Sausage Production Line – Ainister , The product will supply to all over the world, such as: Johannesburg, moldova, kazakhstan, Actually need to any of those objects be of interest to you, make sure you allow us to know. We'll be delighted to present you a quotation on receipt of one's comprehensive specs. We've our individual specialist R&D enginners to meet any of the requriements, We look forward to receiving your enquires soon and hope to have the chance to work together with you inside the future. Welcome to take a look at our organization.

1.Do you provide goods or equipment, or solutions?

We do not produce final products, but are manufacturers of food processing equipment, and we also integrate and provide complete production lines for food processing plants.

2.What areas do your products and services involve?

As an integrator of the production line program of Helper Group, we not only provide various food processing equipment, such as: vacuum filling machine, chopping machine, automatic punching machine, automatic baking oven, vacuum mixer, vacuum tumbler, frozen meat/ Fresh meat grinder, noodle making machine, dumpling making machine, etc.

We also provide the following factory solutions, such as:

Sausage processing plants,noodle processing plants, dumpling plants, canned food processing plants, pet food processing plants, etc., involve a wide range of different food processing and production fields.

3.Which countries are your equipment exported to?

Our customers are all over the world, including the United States, Canada, Colombia, Germany, France, Turkey, South Korea, Singapore, Vietnam, Malaysia, Saudi Arabia, India, South Africa and more than 40 countries and regions, providing customized solutions for different customers.

4.How do you guarantee the installation and after-sales service of the equipment?

We have an experienced technical team and production workers, who can provide remote guidance, on-site installation and other services. The professional after-sales team can communicate remotely at the first time, and even on-site repairs.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.