Personlized Products Sausage Grinder And Stuffer - Pelmeni Production Line – Ainister

Personlized Products Sausage Grinder And Stuffer - Pelmeni Production Line – Ainister Detail:

Pelmeni (Pelmeni/ пельме́ни,) is a Russian-style dumpling whose name is derived from the original text of пельнянь meaning “ear bread”. Pimani dumplings are usually made of unfermented thin dough wrapped in ground meat, fish or vegetarian fillings. Its origin can be traced back to Siberia, but now it has become a national cuisine of Russia, and it has also set off a new trend around the world.Pimanni dumplings are usually cooked in water until cooked, then seasoned with yogurt and served on a plate. They are very similar to Polish dumplings (pierogi), Ukrainian dumplings (Varenyky), Chinese dumplings, and even ravioli.The pelmeni maker can produce different requirements of all these dumplings

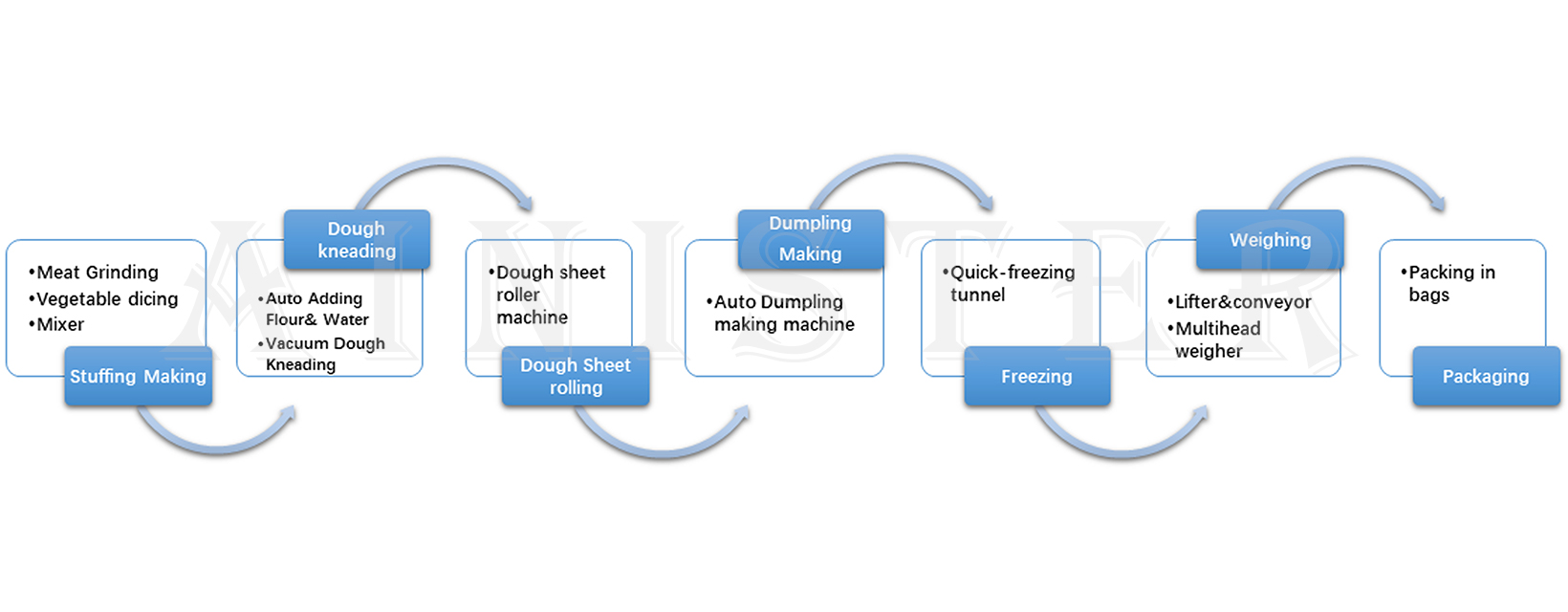

For the production of stuffing, normally vegetables and meat will be processed separately. For vegetable processing, you can choose a multifunctional vegetable cutter, which can automatically cut, shred, slice, and cut leafy vegetables, roots and other vegetables, such as green onions,celery, peppers, cabbage, carrots, potatoes, onions, cucumbers and ginger, even ham and meat. Not only the shape, thickness and length can be adjusted, there are also a variety of cutter heads to choose from.

The pelmeni making machine is the key to the quality of the pelmeni in pelmeni production line, and it is critical to the taste, appearance, and fullness of the final Russian dumplings. After putting the finished dough and fillings into the pelmeni(russian dumpling) forming machine, you can start mass production of handmade Russian dumplings through simple machine parameter settings.Our dumpling making machine is controlled by touch screen and PLC. The speed can be adjusted. It is made of food-grade stainless steel 304 and can be replaced with different molds to meet different product needs.

The automatic pelmeni maker adopts a single-piece integrated chain transmission mode, and multiple rows are formed at the same time. With the servo control system, the positioning is accurate, high-speed and stable, and the product shape is uniform and beautiful. The reasonable mechanical structure design and complete control system ensure that the forming speed of the dumpling machine can reach 360 pieces per minute.

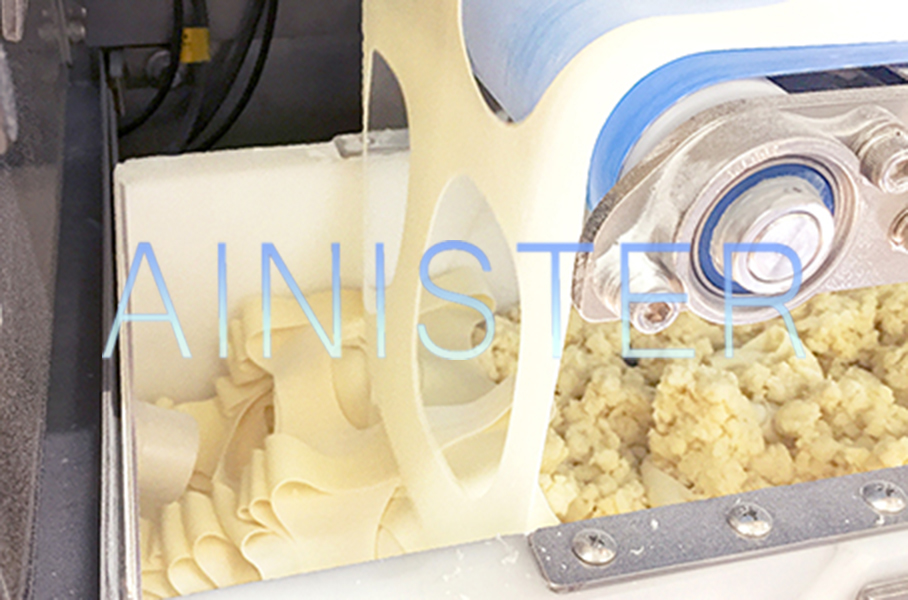

The pelmeni making machine is equipped with a dough sheet pressing system and dough sheet recovery device. The multiple pressing rollers ensure that the thickness of the dough wrapper can be adjusted to 0.2-0.6mm. While ensuring the toughness of the dough, it also improves the taste of dumplings. Equipped with the photoelectric sensors to automatically adjust the dough sheet pressing and feeding process. No need to check manually, improve efficiency and reduce labor costs.

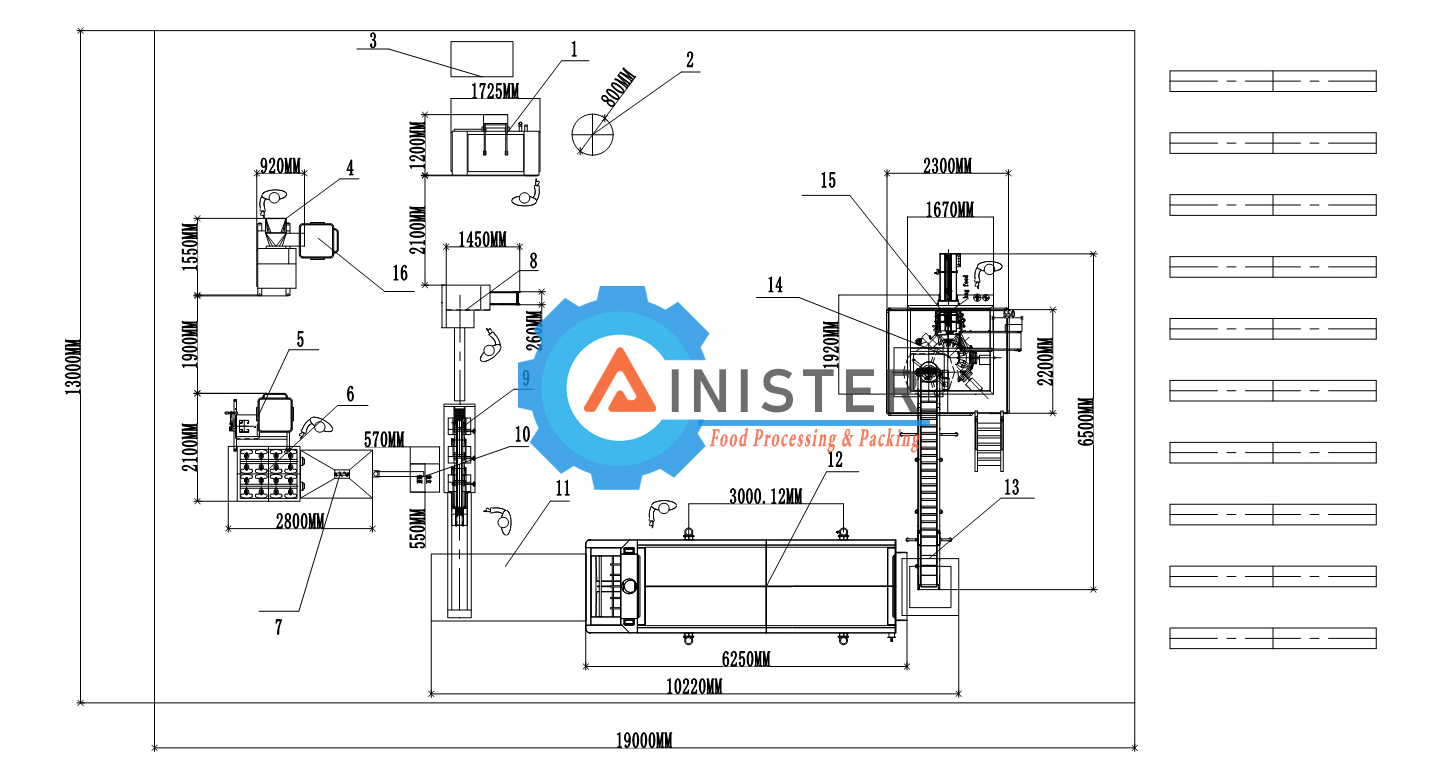

Specification and Technical Parameter

- 1. Compressed Air:0.06 Mpa

- 2. Steam Pressure:0.06-0.08 Mpa

- 3. Power: 3~380V/220V Or Customized according to different voltages.

- 4. Production Capacity:200kg-400kg per hour.

- 5. Applicable Products: Boiled dumplings, frozen dumplings, Pelmeni, Russian dumpling,wonton

- 6. Warranty Period: One year

- 7. Quality Certification: ISO9001, CE, UL

Product detail pictures:

Related Product Guide:

We now have a specialist, efficiency workforce to deliver excellent service for our purchaser. We always follow the tenet of customer-oriented, details-focused for Personlized Products Sausage Grinder And Stuffer - Pelmeni Production Line – Ainister , The product will supply to all over the world, such as: Seychelles, Colombia, El Salvador, we have 8 years experience of production and 5 years experience in trading with the customers all over the world. our clients mainly distributed in the North America, Africa and Eastern Europe. we can supply high quality products with the very competitive price.

1.Do you provide goods or equipment, or solutions?

We do not produce final products, but are manufacturers of food processing equipment, and we also integrate and provide complete production lines for food processing plants.

2.What areas do your products and services involve?

As an integrator of the production line program of Helper Group, we not only provide various food processing equipment, such as: vacuum filling machine, chopping machine, automatic punching machine, automatic baking oven, vacuum mixer, vacuum tumbler, frozen meat/ Fresh meat grinder, noodle making machine, dumpling making machine, etc.

We also provide the following factory solutions, such as:

Sausage processing plants,noodle processing plants, dumpling plants, canned food processing plants, pet food processing plants, etc., involve a wide range of different food processing and production fields.

3.Which countries are your equipment exported to?

Our customers are all over the world, including the United States, Canada, Colombia, Germany, France, Turkey, South Korea, Singapore, Vietnam, Malaysia, Saudi Arabia, India, South Africa and more than 40 countries and regions, providing customized solutions for different customers.

4.How do you guarantee the installation and after-sales service of the equipment?

We have an experienced technical team and production workers, who can provide remote guidance, on-site installation and other services. The professional after-sales team can communicate remotely at the first time, and even on-site repairs.

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.