One of Hottest for Small Gyoza Making Machine - Meat Patty Production Line – Ainister

One of Hottest for Small Gyoza Making Machine - Meat Patty Production Line – Ainister Detail:

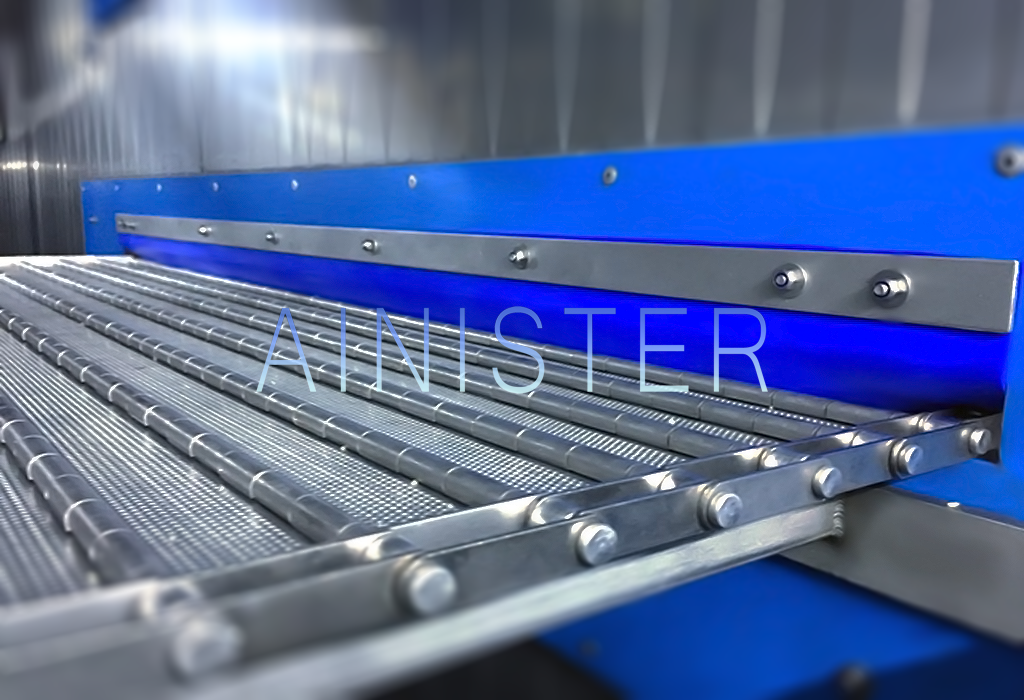

The whole machine is made of stainless steel and other food materials, which meets hygienic standards and HACCP standards, which is easy to clean; the whole machine is designed with safe electrical appliances. Wide range of uses, and a wide range of applicable raw materials, and abundant products. In addition, it is equipped with a sizing machine and a breading machine to become a hamburger patty, chicken chop, and fish patty production line.

In the process of raw meat processing, the meat grinder can prevent the material from heating up too fast and maintain the freshness of the material, and then add auxiliary materials to meet the production requirements.

The automatic meatloaf forming machine can automatically complete filling, forming, stickers (optional), output and other processes. By changing different molds, products of different shapes (round, square, oval, triangle, heart and other shapes) can be produced.

The production line can be equipped with quick freezing equipment for easy storage. The quick freezing production line can be matched with spiral quick freezing or quick freezing tunnel according to the production environment. At the same time, you can choose different refrigeration methods, compressor refrigeration, or liquid nitrogen refrigeration.

Product detail pictures:

Related Product Guide:

With our leading technology also as our spirit of innovation,mutual cooperation, benefits and development, we are going to build a prosperous future jointly with your esteemed company for One of Hottest for Small Gyoza Making Machine - Meat Patty Production Line – Ainister , The product will supply to all over the world, such as: US, Brazil, Jeddah, We pursue the management tenet of "Quality is superior, Service is supreme, Reputation is first", and will sincerely create and share success with all clients. We welcome you to contact us for more information and look forward to working with you.

1.Do you provide goods or equipment, or solutions?

We do not produce final products, but are manufacturers of food processing equipment, and we also integrate and provide complete production lines for food processing plants.

2.What areas do your products and services involve?

As an integrator of the production line program of Helper Group, we not only provide various food processing equipment, such as: vacuum filling machine, chopping machine, automatic punching machine, automatic baking oven, vacuum mixer, vacuum tumbler, frozen meat/ Fresh meat grinder, noodle making machine, dumpling making machine, etc.

We also provide the following factory solutions, such as:

Sausage processing plants,noodle processing plants, dumpling plants, canned food processing plants, pet food processing plants, etc., involve a wide range of different food processing and production fields.

3.Which countries are your equipment exported to?

Our customers are all over the world, including the United States, Canada, Colombia, Germany, France, Turkey, South Korea, Singapore, Vietnam, Malaysia, Saudi Arabia, India, South Africa and more than 40 countries and regions, providing customized solutions for different customers.

4.How do you guarantee the installation and after-sales service of the equipment?

We have an experienced technical team and production workers, who can provide remote guidance, on-site installation and other services. The professional after-sales team can communicate remotely at the first time, and even on-site repairs.

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.