OEM Manufacturer Industrial Meat Grinders - Meatball Production Line – Ainister

OEM Manufacturer Industrial Meat Grinders - Meatball Production Line – Ainister Detail:

Meatballs are very common and consumed in almost every country of the worldThis production line is all food-grade 304 stainless steel with a centralized control system, which is suitable for different raw materials, including beef, chicken, pork, etc., and can also be suitable for special products, such as meatball products containing vegetables and other particles.Can meet various production needs.

Whether it is fresh meat or frozen meat as raw materials, it needs to be ground into meat particles through a meat grinder. The hole plate of the meat grinder can be equipped from 3mm to 27mm, and can be exchanged according to the production demand and process.With a large feed inlet design, it is suitable for materials of different sizes with small temperature changes. It can also be used for the processing of wet mushrooms, peanuts, sesame and other products.

The chopper is an indispensable equipment for the processing of meat products such as sausages and balls. It can not only finely chop the lumpy raw materials, but also mix other raw materials such as water, condiments, and other additional raw materials into a uniform The milky substance can improve the emulsification degree of the raw materials without oil drag, which plays a vital role in improving the taste of the product and increasing the yield of the product.

In addition to the choice of raw materials, the elasticity and toughness of meatballs are more important in the production of meat fillings. The indispensable process is beating.The high-speed pulping machine can improve meat fat fiber in the production process. The produced meatballs are smooth and tender, low-fat, taste crisp, good elasticity, and will not be broken by cooking a long time. The barrel is turned over by hydraulic lifting and adopts a double-layer insulation. Ensure the freshness of materials.Stainless steel body, frequency converter speed regulation, according to the process selection.

The core process of meatball production-forming.The meatball forming machine adopts a continuous output meatball system with high production efficiency. It is equipped with knives and formers of different calibers, which can be replaced at will.The meatball forming equipment uses copper gears and is wear-resistant. It is equipped with molds of different sizes and is suitable for different product needs. The forming speed is fast and the shape is good. Easy to disassemble and maintain.

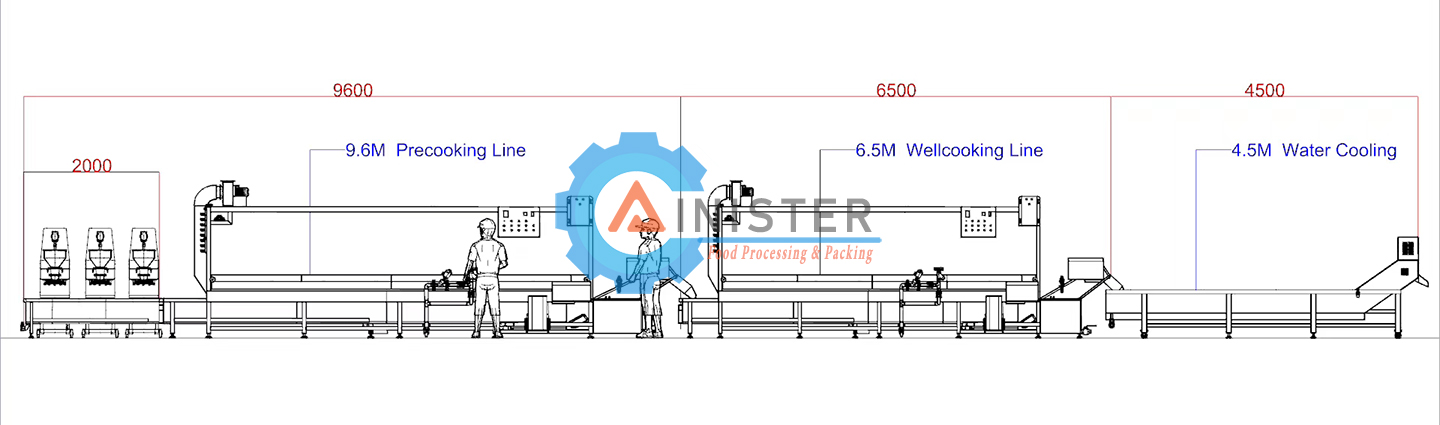

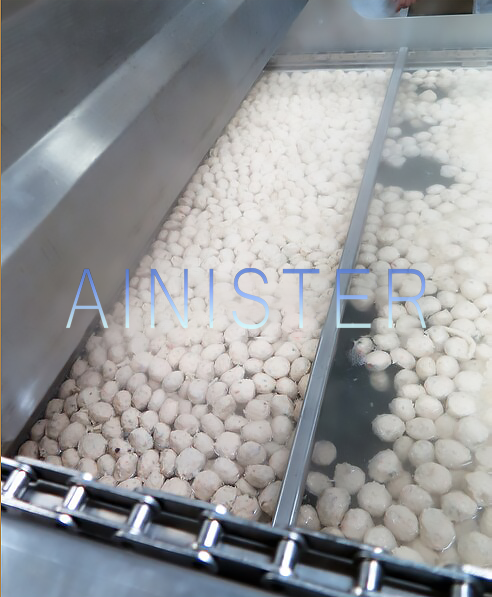

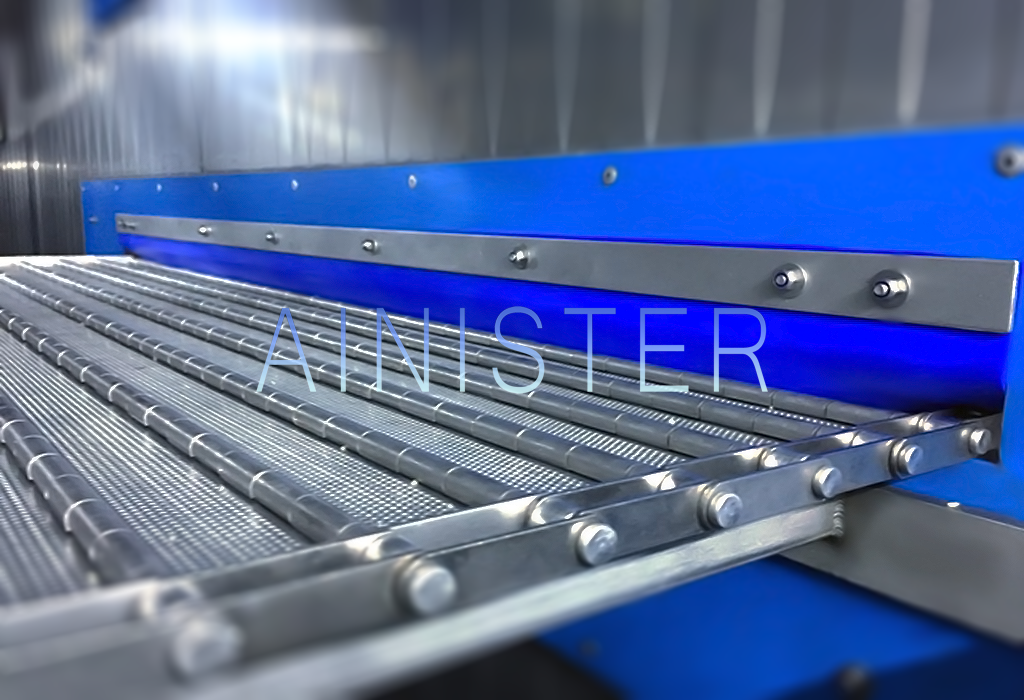

The meatball boiling line consists of three parts, namely the forming part, the cooking part and the cooling part.The meatball boiled line is generally pre-cooked at low temperature, then cooked at high temperature, and finally cooled by water circulation. The water in the forming tank and the cooking tank is heated by steam pipes in the two tanks. The water temperature is controlled by adjusting the steamer to ensure that the water temperature of the forming tank is about 75°C and the water temperature of the cooking tank is about 90°C.The temperature of the production line is controllable and the speed is adjustable. Different products can match different transmission structures.

The production line can be equipped with quick freezing equipment for easy storage. The quick freezing production line can be matched with spiral quick freezing or quick freezing tunnel according to the production environment. At the same time, you can choose different refrigeration methods, compressor refrigeration, or liquid nitrogen refrigeration.

Product detail pictures:

Related Product Guide:

We are also focusing on enhancing the things administration and QC program in order that we could keep fantastic advantage within the fiercely-competitive enterprise for OEM Manufacturer Industrial Meat Grinders - Meatball Production Line – Ainister , The product will supply to all over the world, such as: Buenos Aires, Anguilla, Muscat, Taking the core concept of "to be the Responsible". We will redound up on society for high quality products and good service. We will initiative to participate in international competition to be a first- class manufacturer of this product in the world.

1.Do you provide goods or equipment, or solutions?

We do not produce final products, but are manufacturers of food processing equipment, and we also integrate and provide complete production lines for food processing plants.

2.What areas do your products and services involve?

As an integrator of the production line program of Helper Group, we not only provide various food processing equipment, such as: vacuum filling machine, chopping machine, automatic punching machine, automatic baking oven, vacuum mixer, vacuum tumbler, frozen meat/ Fresh meat grinder, noodle making machine, dumpling making machine, etc.

We also provide the following factory solutions, such as:

Sausage processing plants,noodle processing plants, dumpling plants, canned food processing plants, pet food processing plants, etc., involve a wide range of different food processing and production fields.

3.Which countries are your equipment exported to?

Our customers are all over the world, including the United States, Canada, Colombia, Germany, France, Turkey, South Korea, Singapore, Vietnam, Malaysia, Saudi Arabia, India, South Africa and more than 40 countries and regions, providing customized solutions for different customers.

4.How do you guarantee the installation and after-sales service of the equipment?

We have an experienced technical team and production workers, who can provide remote guidance, on-site installation and other services. The professional after-sales team can communicate remotely at the first time, and even on-site repairs.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.