Good quality Production Of Cassava Noodles - Bacon Production Line – Ainister

Good quality Production Of Cassava Noodles - Bacon Production Line – Ainister Detail:

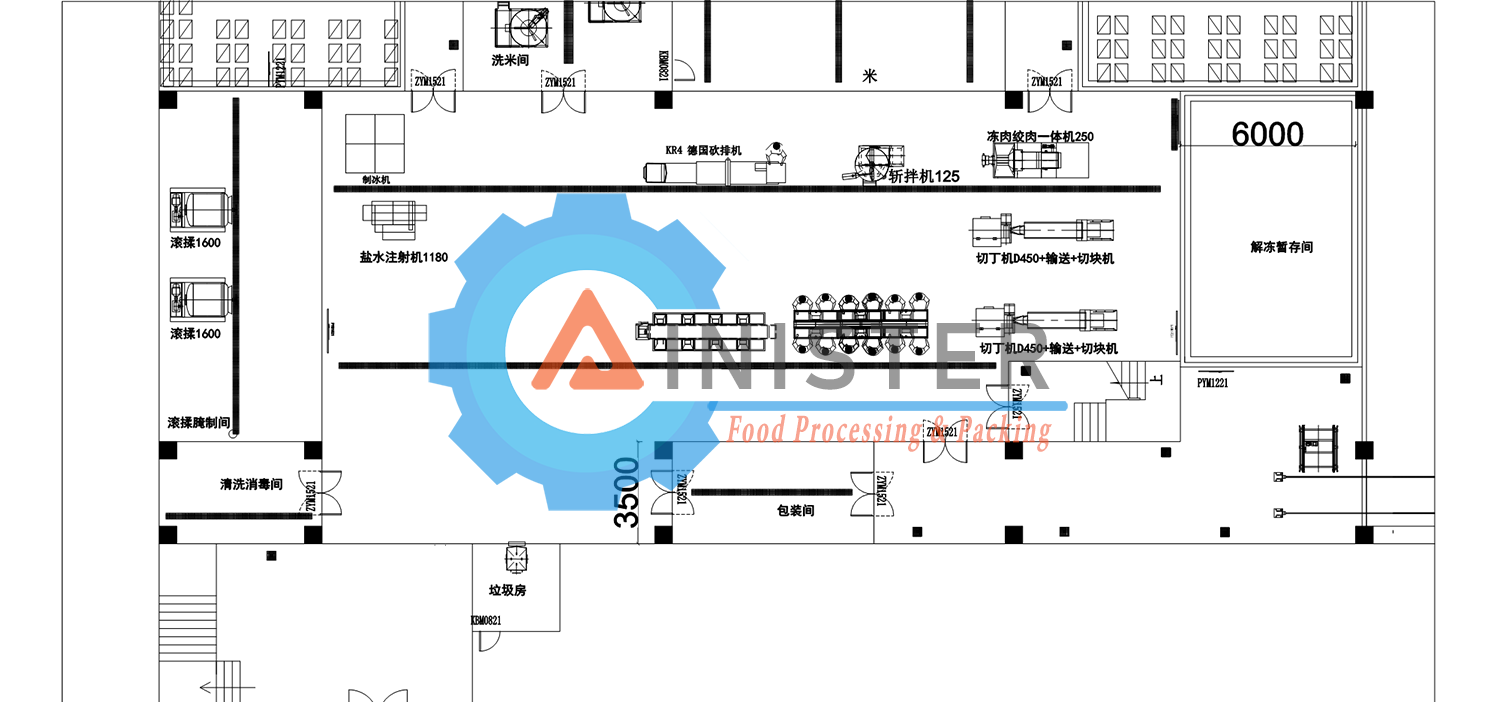

The bacon production line is an automated production solution on the basis of retaining the traditional processing technology. It ensures the characteristics and advantages of bacon products, while increasing production capacity and reducing labor costs. Thanks to the high-quality materials and precise control of the equipment, the visual operation is realized and the production is more transparent.

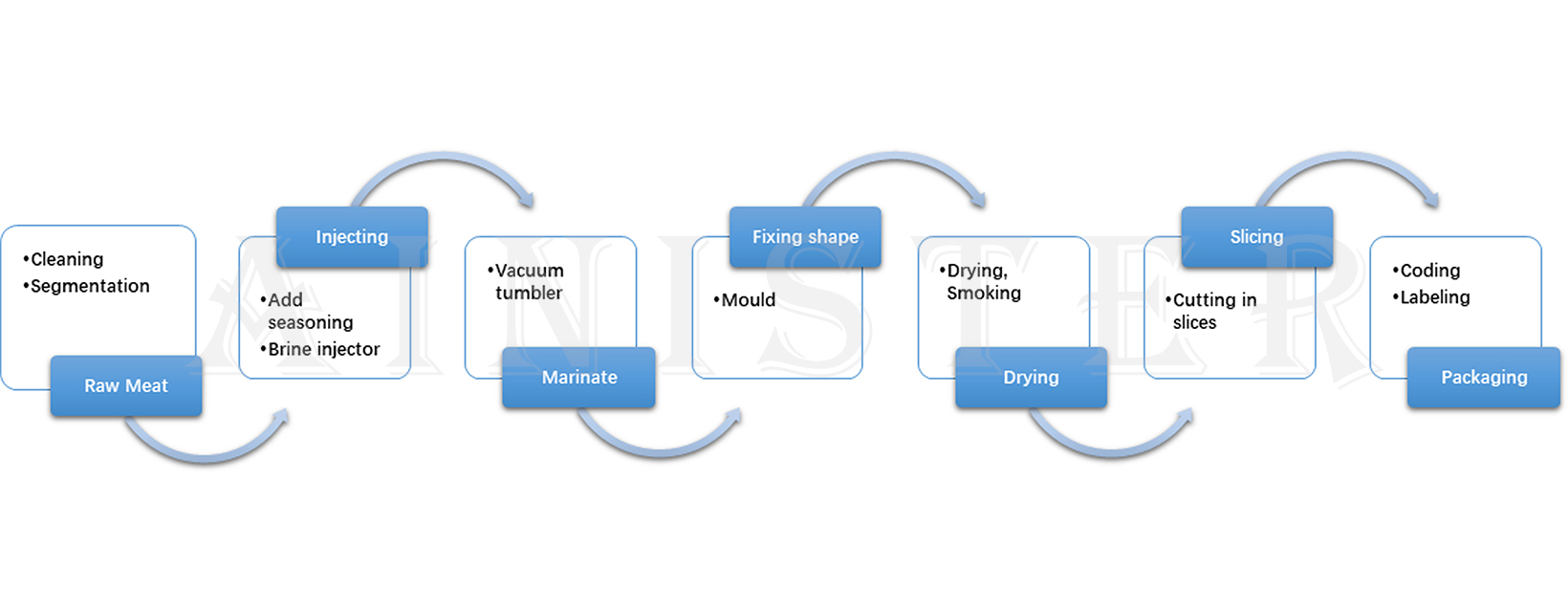

Bacon has higher requirements for raw materials, and lean pork is generally used. First, pork needs to be removed from the bone. Then use a peeling machine to remove the skin of the pork. The peeling machine adopts an adjustable knife seat, which is convenient to adjust the thickness of the peeling. It uses a high-quality German knife set, which has a good peeling effect and simple operation.

In order to make the bacon more delicious, in the modern production plan, the pickled condiments will be injected into the raw meat through the injection machine to avoid the poor taste of the product due to insufficient pickling time and uneven absorption of the pickled sauce. Our brine injection machine is suitable for different production needs. It adopts German water pump, frequency converter speed control, touch screen control, brine tank adopts three-stage filtration, equipped with agitator, so that the injection effect is better.

Pickling is an important process in bacon processing, which determines the taste and quality of the finished product. The traditional marinating process generally chooses to put the seasonings in the container and let it standstill. The modern process can choose to use the tumbler for marinating, which can realize timing tumbling and tapping in the vacuum state so that the meat can better taste and save the marinating time. Reduce unnecessary labor consumption.

Smoking is an important process that determines the taste and color of bacon. Modern production tends to use smokers for production. The smoker uses a stainless steel body, which has the functions of drying, cooking, humidifying, baking, coloring, and exhausting smoke. The body is filled with high-performance insulation materials, with good airtightness, energy saving and high efficiency. Equipped with large-size touch screen and brand PLC control system, it can store 99 kinds of craft formulas to meet different product craft requirements.

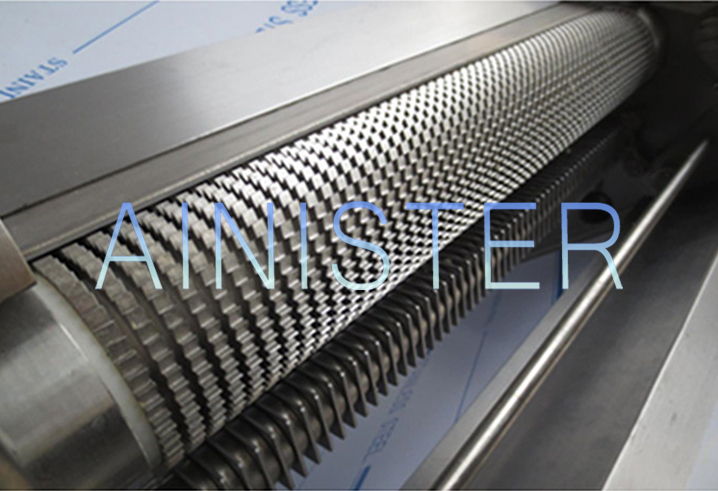

For slicing bacon, an automatic slicer is generally used. The thruster automatically returns to positioning, saving time and improving efficiency; equipped with safety guards and detection sensors, the blade is directly connected to the drive motor, which greatly improves the accuracy of cutting and portioning; by replacing the smooth blade knife, toothed single knife, etc. To realize functions such as slicing and portioning. Suitable for slicing raw materials such as pork and beef ribs, spine bones (not including strong bones such as leg bones), all kinds of boneless meat, all kinds of cooked meat, steak, bacon, all kinds of fish, cheese and other raw materials above -5°C.

For the packaging part, vacuum packaging machines are used, and different types of skin packaging machines, thermoforming vacuum packaging machines, vacuum tray sealer, etc. can be selected according to the final packaging type. All stainless steel body adopts German original vacuum pump, fast matching speed, low failure rate, and beautiful packaging effect. By changing the packaging mold and packaging film material to meet different packaging requirements.

Specification and Technical Parameter

- 1. Compressed Air:0.06 Mpa

- 2. Steam Pressure:0.06-0.08 Mpa

- 3. Power:3~380V/220V Or Customized according to different voltages.

- 4. Production Capacity:100kg-2000kg per hour.

- 5. Applicable Products: smoked bacon, fryer bacon, backed bacon, etc.

- 6. Warranty Period: One year

- 7. Quality Certification: ISO9001, CE, UL

Product detail pictures:

Related Product Guide:

We constantly think and practice corresponding to the change of circumstance, and grow up. We aim at the achievement of a richer mind and body along with the living for Good quality Production Of Cassava Noodles - Bacon Production Line – Ainister , The product will supply to all over the world, such as: United Arab Emirates, Hungary, Russia, When you are keen on any of our items following you view our product list, please feel free to make contact with us for inquiries. You'll be able to send us emails and get in touch with us for consultation and we shall respond to you as soon as we are able to. If it's convenient, you could find out our address in our web site and come to our enterprise. or additional information of our items by yourself. We're generally ready to build lengthy and steady co-operation relations with any possible shoppers within the associated fields.

1.Do you provide goods or equipment, or solutions?

We do not produce final products, but are manufacturers of food processing equipment, and we also integrate and provide complete production lines for food processing plants.

2.What areas do your products and services involve?

As an integrator of the production line program of Helper Group, we not only provide various food processing equipment, such as: vacuum filling machine, chopping machine, automatic punching machine, automatic baking oven, vacuum mixer, vacuum tumbler, frozen meat/ Fresh meat grinder, noodle making machine, dumpling making machine, etc.

We also provide the following factory solutions, such as:

Sausage processing plants,noodle processing plants, dumpling plants, canned food processing plants, pet food processing plants, etc., involve a wide range of different food processing and production fields.

3.Which countries are your equipment exported to?

Our customers are all over the world, including the United States, Canada, Colombia, Germany, France, Turkey, South Korea, Singapore, Vietnam, Malaysia, Saudi Arabia, India, South Africa and more than 40 countries and regions, providing customized solutions for different customers.

4.How do you guarantee the installation and after-sales service of the equipment?

We have an experienced technical team and production workers, who can provide remote guidance, on-site installation and other services. The professional after-sales team can communicate remotely at the first time, and even on-site repairs.

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!