Factory making Juicy Jelly Candy Production Line - Bagged pet food production line – Ainister

Factory making Juicy Jelly Candy Production Line - Bagged pet food production line – Ainister Detail:

The pet food market has been developing rapidly, and people’s requirements for pet food are becoming higher and higher. Whether you are producing several hundred kilograms per day or several tons per hour, We can help customers to design customized solutions. Provide beneficial help for your development.

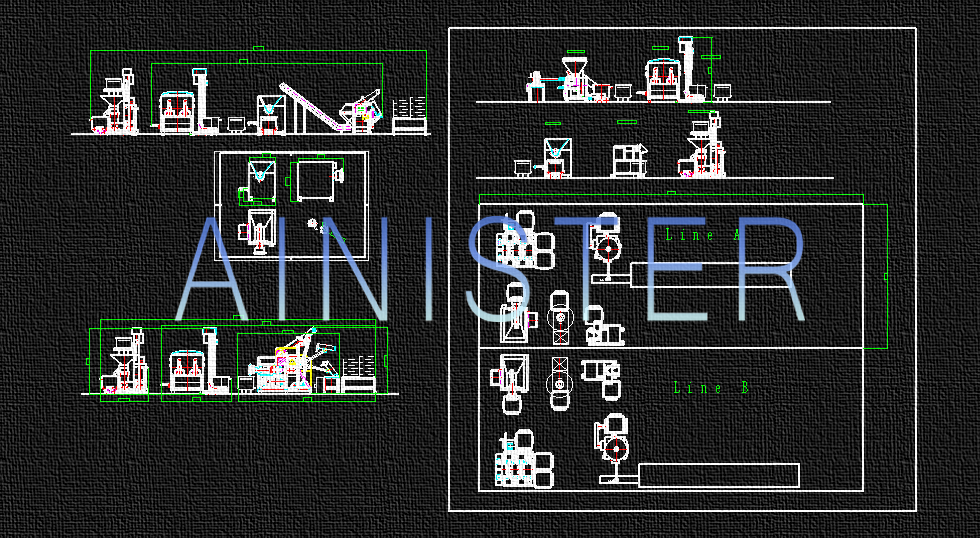

Customized layout according to factory size, From raw material processing to extrusion, to the final packaging, the entire production line. Just provide us with your product requirements, output, and factory size, we will design a suitable plant.

Suitable for the processing of different raw materials, frozen meat, fresh meat, vegetables, additives, etc., compact structure, does not occupy too much space. In the pre-processing of raw materials, we will follow the requirements of customers, or according to our experience and suggestions.

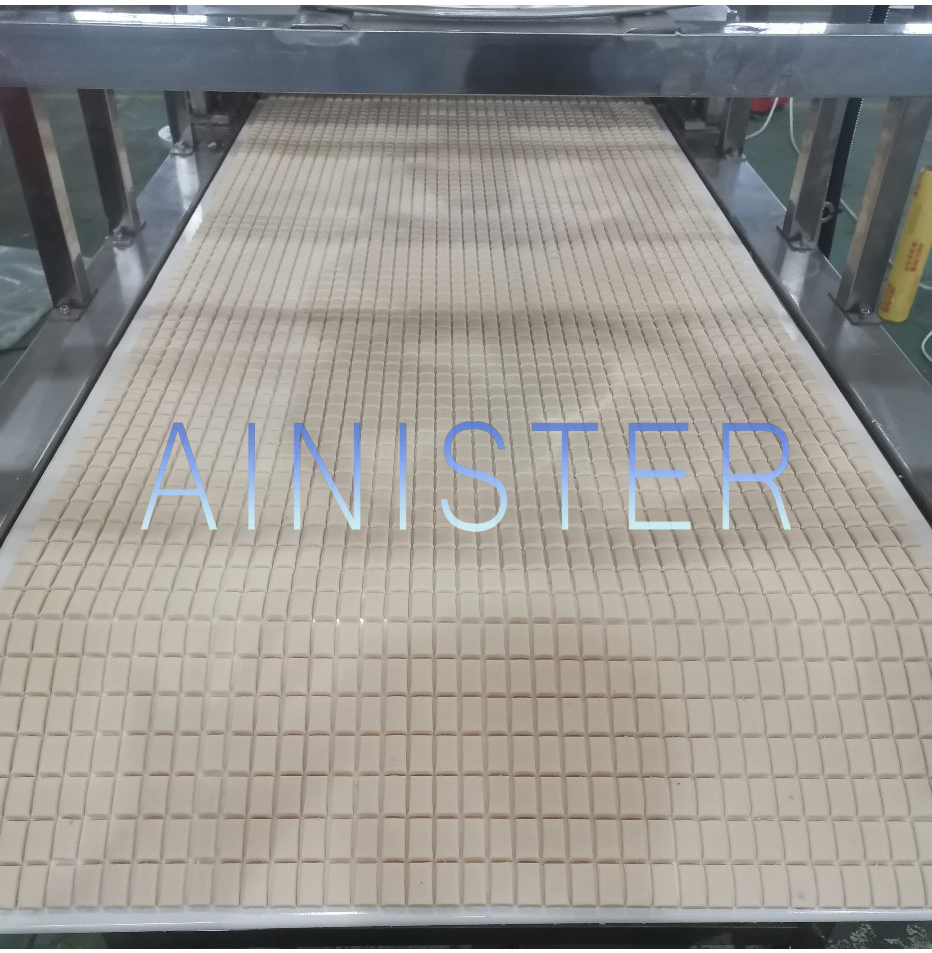

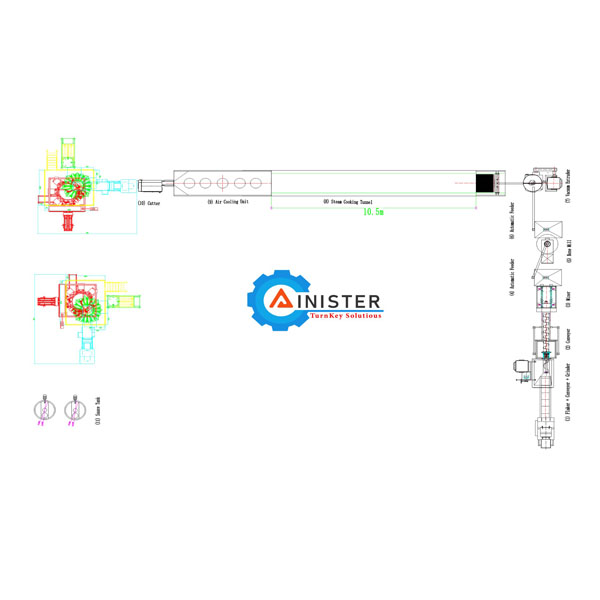

The vacuum filling series is used for the extrusion system, and the flow divider is used to ensure the filling speed and quantitative accuracy. With different shaping mold, products with different shapes and specifications can be made. Optional automatic cut-off function to achieve automatic production and reduce labor costs.

The steam tunnel furnace has uniform heating, simple operation and good heating effect. The interlayer is filled with high-quality insulation materials. Touch screen operation, PLC precise temperature control.

Product detail pictures:

Related Product Guide:

With our excellent administration, strong technical capability and strict excellent control method, we carry on to offer our clients with responsible good quality, reasonable costs and great companies. We intention at becoming considered one of your most responsible partners and earning your pleasure for Factory making Juicy Jelly Candy Production Line - Bagged pet food production line – Ainister , The product will supply to all over the world, such as: Bahrain, Dominica, America, Our solutions are produced with the best raw materials. Every moment, we constantly improve the production programme. In order to ensure better quality and service, we now have been focusing on the production process. We have got high praise by partner. We are looking forward to establishing business relationship with you.

1.Do you provide goods or equipment, or solutions?

We do not produce final products, but are manufacturers of food processing equipment, and we also integrate and provide complete production lines for food processing plants.

2.What areas do your products and services involve?

As an integrator of the production line program of Helper Group, we not only provide various food processing equipment, such as: vacuum filling machine, chopping machine, automatic punching machine, automatic baking oven, vacuum mixer, vacuum tumbler, frozen meat/ Fresh meat grinder, noodle making machine, dumpling making machine, etc.

We also provide the following factory solutions, such as:

Sausage processing plants,noodle processing plants, dumpling plants, canned food processing plants, pet food processing plants, etc., involve a wide range of different food processing and production fields.

3.Which countries are your equipment exported to?

Our customers are all over the world, including the United States, Canada, Colombia, Germany, France, Turkey, South Korea, Singapore, Vietnam, Malaysia, Saudi Arabia, India, South Africa and more than 40 countries and regions, providing customized solutions for different customers.

4.How do you guarantee the installation and after-sales service of the equipment?

We have an experienced technical team and production workers, who can provide remote guidance, on-site installation and other services. The professional after-sales team can communicate remotely at the first time, and even on-site repairs.

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.