Factory best selling Casing Juicy Jelly Production Solution - Fresh Noodles Production Line – Ainister

Factory best selling Casing Juicy Jelly Production Solution - Fresh Noodles Production Line – Ainister Detail:

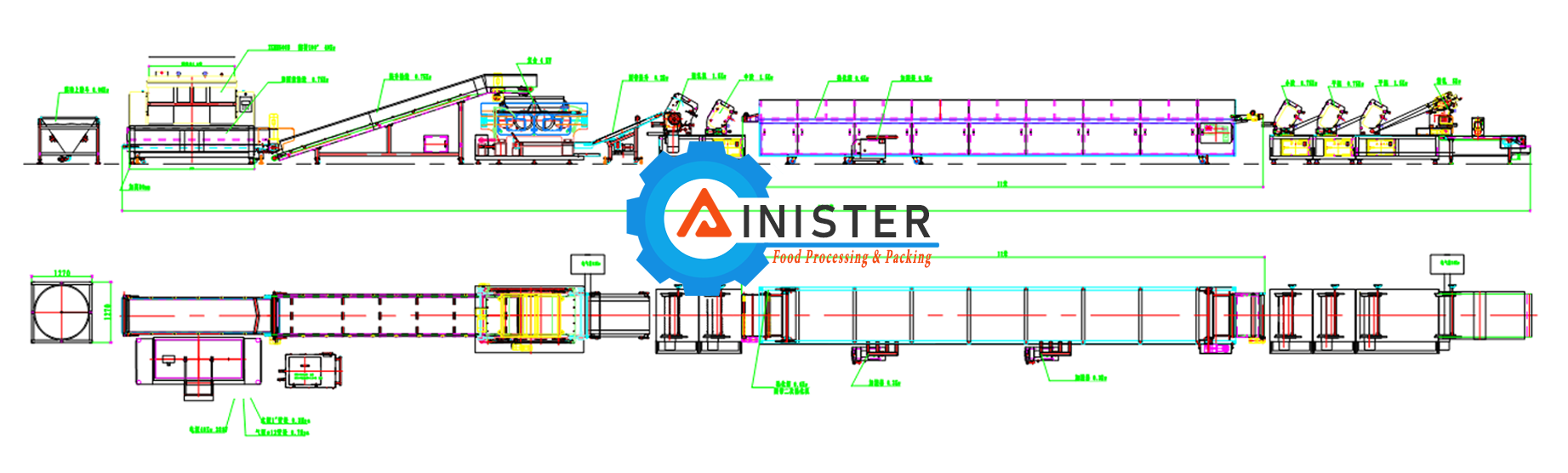

Noodles, as one of the most popular foods in the world, can be found anywhere. There are many types of noodles, fresh noodles, semi-dry noodles, frozen noodles, cooked noodles, fried noodles and so on. We have more than 20 years of experience in the production of noodles equipment. In China, we provide equipment to the largest noodle production companies. In other countries and regions, we also provide technical support and customized services for different customers and have gained a good reputation.

Fresh noodles are mainly popular in Asia. Due to the large population, the consumption of noodles has always been high. We can provide a complete set of fresh noodle production line equipment.The main body of the equipment adopts a 304 high-quality stainless steel structure to avoid the corrosion and service life problems caused by the traditional cast body. At the same time, it reduces equipment wear caused by long-term operation.

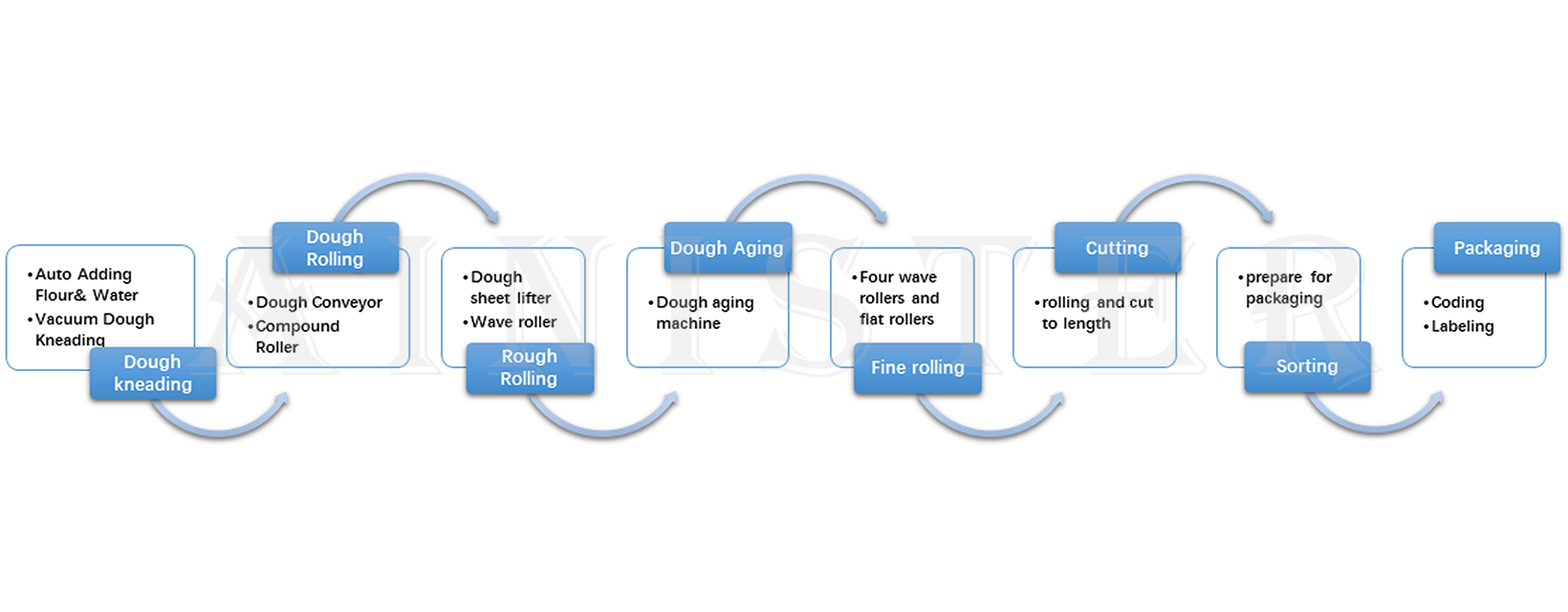

The basic equipment for noodle production is a vacuum dough kneading machine. The vacuum dough kneading machine is developed by our research group independently, as the most advanced dough kneader/mixer, it is suitable for all kinds of pasta products processing, you can achieve different dough kneading effects by the different types of stirring shafts up to the features of wheat powder.It can also be equipped with automatic flour adding and automatic water filling functions to further realize automatic production.

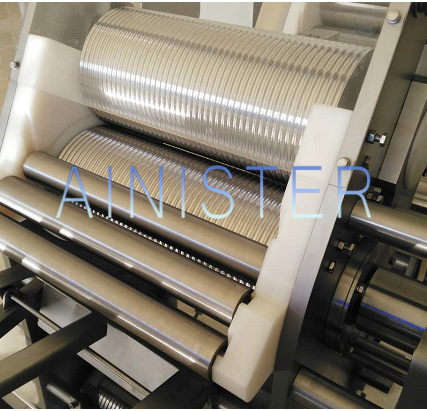

The kneaded dough needs to be rolled through multiple processes to form the final noodle. High-precision rolls made of special stainless steel are selected to ensure long term rust resistance. Even the water percentage reaches 50%, with no risk of adhesion of dough. Thus to solve the problem of making noodles with more water.

In order to make the noodles taste better and stronger, we simulated the aging steps of handmade noodles and developed a aging tunnel. At the dough aging step, we set aside the traditional vertical layers aging way, but to select the horizontal suspended type. The dough sheet moves forward slowly and continuously on the hanging sticks at a horizontal level.

In the noodle cutting process, noodles of different specifications can be cut by assembling knife sets of different sizes. In addition,this production line will not only meet the requirements of noodle production but also enlarge your dough wrapper production without increasing working stuff. It adopts with roller cutter and knife cutter in actual production.

The noodles made by the vacuum dough mixer machine have good toughness and strong taste. They will not be rotten for a long time and easy to preserve. With different accessories, they can meet the needs of different tastes.

Specification and Technical Parameter

- 1. Compressed Air:0.06 Mpa

- 2. Steam Pressure:0.06-0.08 Mpa

- 3. Power: 3~380V/220V Or Customized according to different voltages.

- 4. Production Capacity:200kg-2000kg per hour.

- 5. Applicable Products: Fresh noodle, egg noodle, vegetable noodle, etc.

- 6. Warranty Period: One year

- 7. Quality Certification: ISO9001, CE, UL

Product detail pictures:

Related Product Guide:

Persisting in "High quality, Prompt Delivery, Aggressive Price", now we have established long-term cooperation with consumers from equally overseas and domestically and get new and old clients' large comments for Factory best selling Casing Juicy Jelly Production Solution - Fresh Noodles Production Line – Ainister , The product will supply to all over the world, such as: Adelaide, Boston, Hongkong, By adhering to the principle of "human oriented, winning by quality", our company sincerely welcomes merchants from at home and abroad to visit us, talk business with us and jointly create a brilliant future.

1.Do you provide goods or equipment, or solutions?

We do not produce final products, but are manufacturers of food processing equipment, and we also integrate and provide complete production lines for food processing plants.

2.What areas do your products and services involve?

As an integrator of the production line program of Helper Group, we not only provide various food processing equipment, such as: vacuum filling machine, chopping machine, automatic punching machine, automatic baking oven, vacuum mixer, vacuum tumbler, frozen meat/ Fresh meat grinder, noodle making machine, dumpling making machine, etc.

We also provide the following factory solutions, such as:

Sausage processing plants,noodle processing plants, dumpling plants, canned food processing plants, pet food processing plants, etc., involve a wide range of different food processing and production fields.

3.Which countries are your equipment exported to?

Our customers are all over the world, including the United States, Canada, Colombia, Germany, France, Turkey, South Korea, Singapore, Vietnam, Malaysia, Saudi Arabia, India, South Africa and more than 40 countries and regions, providing customized solutions for different customers.

4.How do you guarantee the installation and after-sales service of the equipment?

We have an experienced technical team and production workers, who can provide remote guidance, on-site installation and other services. The professional after-sales team can communicate remotely at the first time, and even on-site repairs.

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!