Dumpling Machine and Production Solution

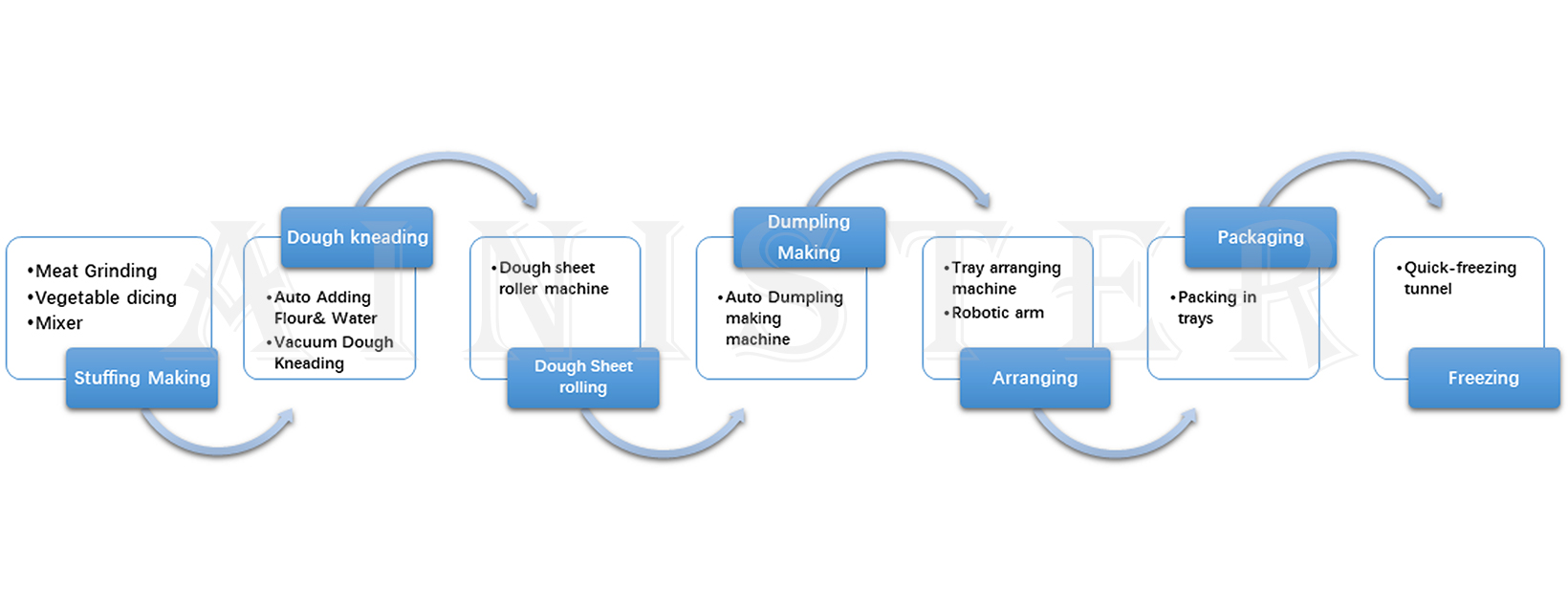

How Dumpling Making Machine Works

Your Dumpling Production Line and Solution Consultant

Food Made by Ainister Dumpling Making Machines

A Dumpling

A Dumpling

A Dumpling

A Dumpling

A Dumpling

Dumpling Production Planning Proposal and Equipment List

Automatic Dumpling Machines

Preparation Equipment in Dumplings Production

Auxiliary Equipment for Dumpling Production Line

Automatic Dumpling Machine Display

Complete Automatic Dumpling Making Machine

It is researched and developed independently by our company, with patent intellectual property right, combining the functions of the wrapper roller, quantitative stuffing, dumpling forming, and wrapper recycling. The process of wrapper producing, stuffing supply, wrapping and sealing, power spreading and shaping are all completed automatically. The dumplings produced are close to hand making ones in the taste, color, and shape etc.

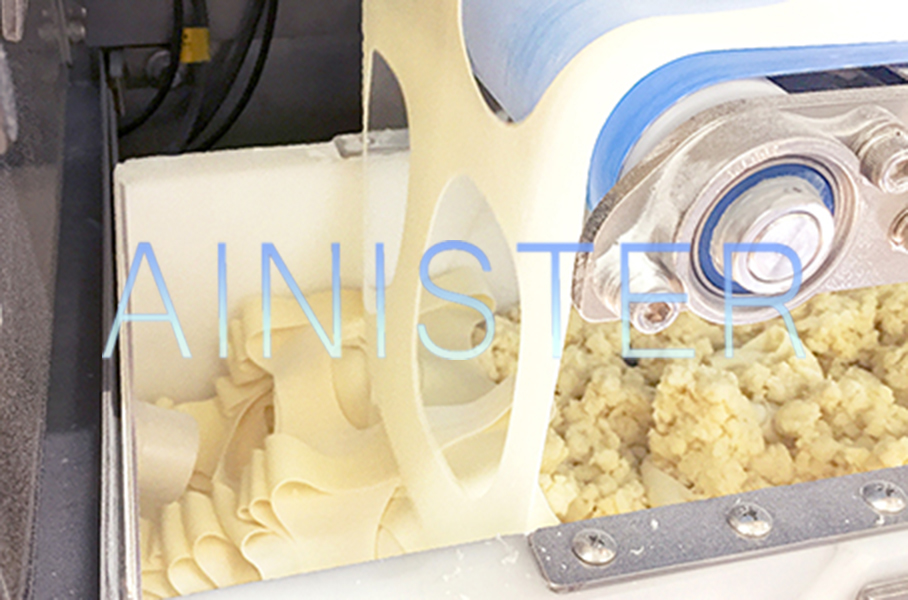

Dumpling Wrapper and Filling

Like ordinary dumplings, the production of dumpling wrapper and dumpling filling is similar, the main difference lies in the forming part.What is the core part of the dumpling production line? Of course it is a dumpling maker machine.Our dumpling machine adopts servo control, with PLC and touch screen, it is convenient to manage different products. The stainless steel body makes the equipment easy to clean and prolongs its service life.

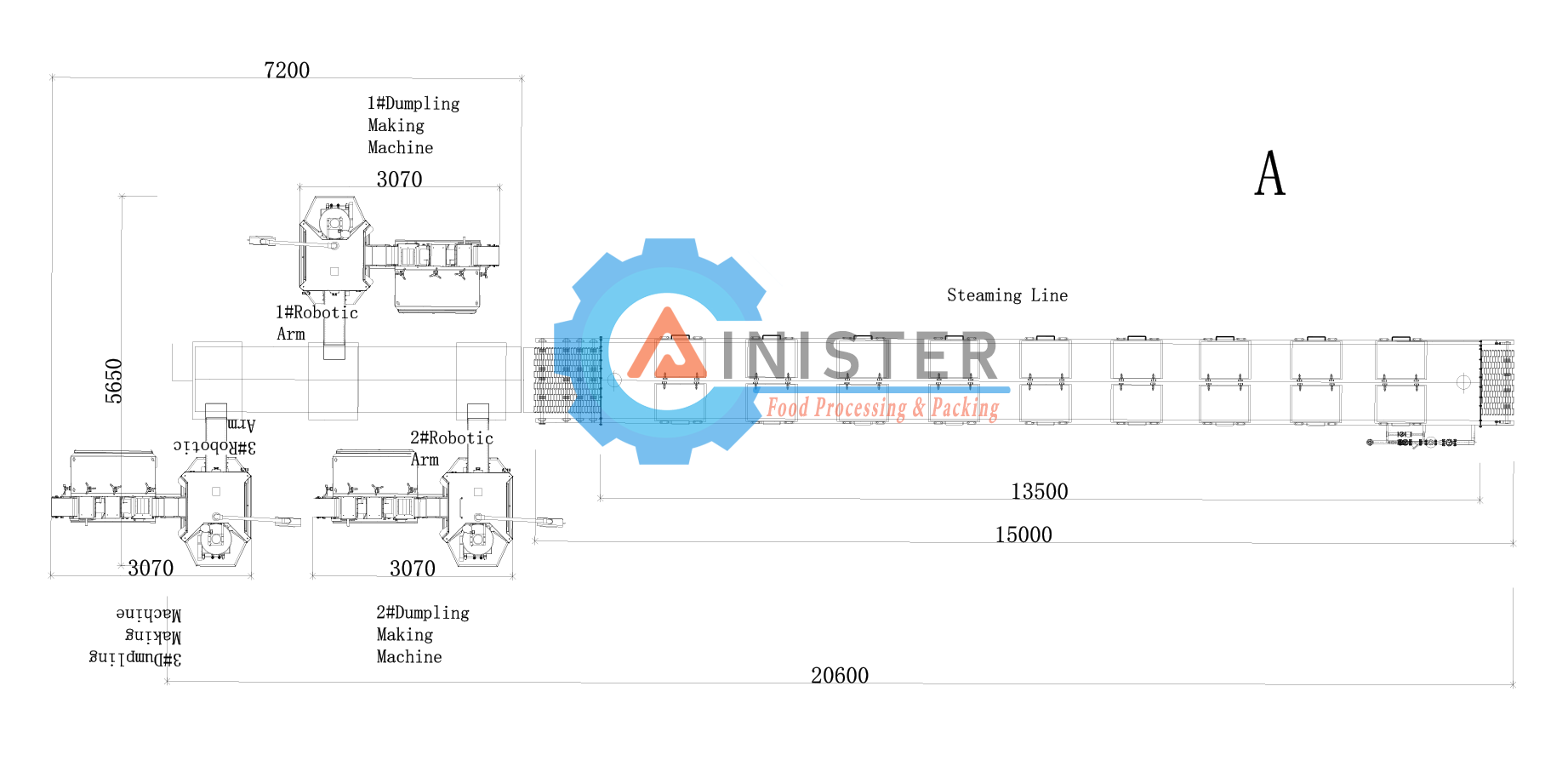

Layout Drawing for Large Dumpling Production Line

Specifications

- 1. Compressed Air:0.06 Mpa

- 2. Steam Pressure:0.06-0.08 Mpa

- 3. Power: 3~380V/220V Or Customized according to different voltages.

- 4. Production Capacity:100kg-2000kg per hour.

- 5. Applicable Products: Steam dumplings, steam gyoza, instant pot dumplings, fried dumplings, etc.

- 6. Warranty Period: One year

- 7. Quality Certification: ISO9001, CE, UL

Suitable For

- * Food factory

a building where machines are equipped to prepare ingredients and make, cook and package food. E.g. frozen food factory, ready meal factory.

- * Kitchen design and equipment supplier

a person or organization that provides production process planning, commercial kitchen appliance, and food making machines.

- * Machine distributor

a person or organization that buys great food machines and sells them to local customers.

- * Entrepreneur who wants to invest in the food industry

someone who starts a new food business and needs a comprehensive solution, including consulting service in equipment purchase and manufacturing know-how.

1.Do you provide goods or equipment, or solutions?

We do not produce final products, but are manufacturers of food processing equipment, and we also integrate and provide complete production lines for food processing plants.

2.What areas do your products and services involve?

As an integrator of the production line program of Helper Group, we not only provide various food processing equipment, such as: vacuum filling machine, chopping machine, automatic punching machine, automatic baking oven, vacuum mixer, vacuum tumbler, frozen meat/ Fresh meat grinder, noodle making machine, dumpling making machine, etc.

We also provide the following factory solutions, such as:

Sausage processing plants,noodle processing plants, dumpling plants, canned food processing plants, pet food processing plants, etc., involve a wide range of different food processing and production fields.

3.Which countries are your equipment exported to?

Our customers are all over the world, including the United States, Canada, Colombia, Germany, France, Turkey, South Korea, Singapore, Vietnam, Malaysia, Saudi Arabia, India, South Africa and more than 40 countries and regions, providing customized solutions for different customers.

4.How do you guarantee the installation and after-sales service of the equipment?

We have an experienced technical team and production workers, who can provide remote guidance, on-site installation and other services. The professional after-sales team can communicate remotely at the first time, and even on-site repairs.