China OEM Steel Vegetable Cutter - Raw Pet Food Processing Line – Ainister

China OEM Steel Vegetable Cutter - Raw Pet Food Processing Line – Ainister Detail:

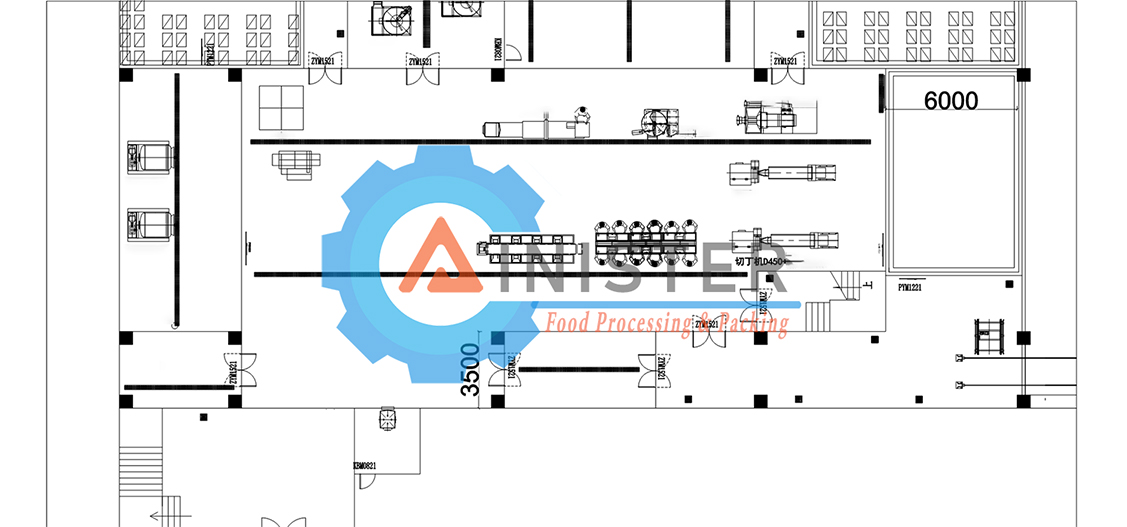

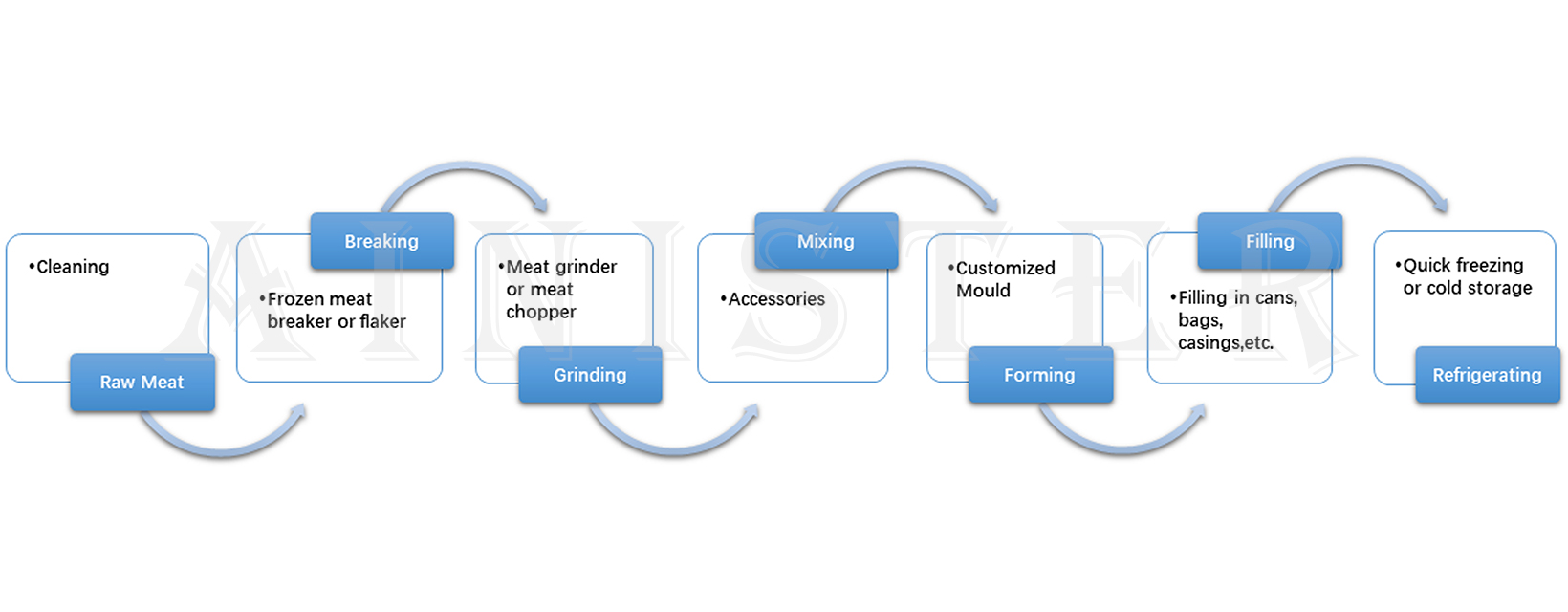

Raw pet food is different from ordinary dry pet food and wet pet food, but the raw materials are divided, cut, and then processed, shaped and filled, and stored directly in quick-frozen packaging. Raw pet food is different from ordinary puffed pet food and steamed pet food. Instead, the raw materials are divided, cut into shapes and filled, and stored directly in quick-frozen packaging. Compared with general products, raw pet food retains more nutritional products, which is more conducive to the growth of pets.

In addition to using meat as raw material, raw pet food also adds different vegetables and other accessories as auxiliary materials in order to balance nutrition. Raw meat generally does not need to go through a complicated process, try to keep the original shape and taste of the meat, usually only need to be divided, ground, and cut.

In order to cater to the diversity of the market, raw meat products can be made into different shapes or packed into different containers and packaging forms. Such as PVC boxes, bags, round, square, special shapes, etc., not only can meet different customer needs, but also facilitate customers to perform secondary processing to suit different pet tastes.

Since the formed product has not been steamed or dried, the shelf life will not be very long. It needs to undergo a quick freezing process and then put it in a cold storage. Compared with dry pet food and wet pet food, raw pet food has a simpler processing technology and a low cost, and the starting point for most investors is not very high.

Specification and Technical Parameter

Compressed Air:0.06 Mpa

Steam Pressure:0.06-0.08 Mpa

Power: 3~380V/220V Or Customized according to different voltages.

Production Capacity:300kg-3000kg per hour.

Applicable Products: Raw pet food, raw dog food, canned raw pet food, etc.

Warranty Period: One year

Quality Certification: ISO9001, CE, UL

Product detail pictures:

Related Product Guide:

We not only will try our greatest to supply outstanding services to every shopper, but also are ready to receive any suggestion offered by our buyers for China OEM Steel Vegetable Cutter - Raw Pet Food Processing Line – Ainister , The product will supply to all over the world, such as: Melbourne, Adelaide, Ecuador, High output volume, top quality, timely delivery and your satisfaction are guaranteed. We welcome all inquiries and comments. If you are interested in any of our products or have an OEM order to fulfill, please feel free to contact us now. Working with us will save you money and time.

1.Do you provide goods or equipment, or solutions?

We do not produce final products, but are manufacturers of food processing equipment, and we also integrate and provide complete production lines for food processing plants.

2.What areas do your products and services involve?

As an integrator of the production line program of Helper Group, we not only provide various food processing equipment, such as: vacuum filling machine, chopping machine, automatic punching machine, automatic baking oven, vacuum mixer, vacuum tumbler, frozen meat/ Fresh meat grinder, noodle making machine, dumpling making machine, etc.

We also provide the following factory solutions, such as:

Sausage processing plants,noodle processing plants, dumpling plants, canned food processing plants, pet food processing plants, etc., involve a wide range of different food processing and production fields.

3.Which countries are your equipment exported to?

Our customers are all over the world, including the United States, Canada, Colombia, Germany, France, Turkey, South Korea, Singapore, Vietnam, Malaysia, Saudi Arabia, India, South Africa and more than 40 countries and regions, providing customized solutions for different customers.

4.How do you guarantee the installation and after-sales service of the equipment?

We have an experienced technical team and production workers, who can provide remote guidance, on-site installation and other services. The professional after-sales team can communicate remotely at the first time, and even on-site repairs.

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!