Best-Selling Dog Food Production Machine - Juicy Gummy Production Line – Ainister

Best-Selling Dog Food Production Machine - Juicy Gummy Production Line – Ainister Detail:

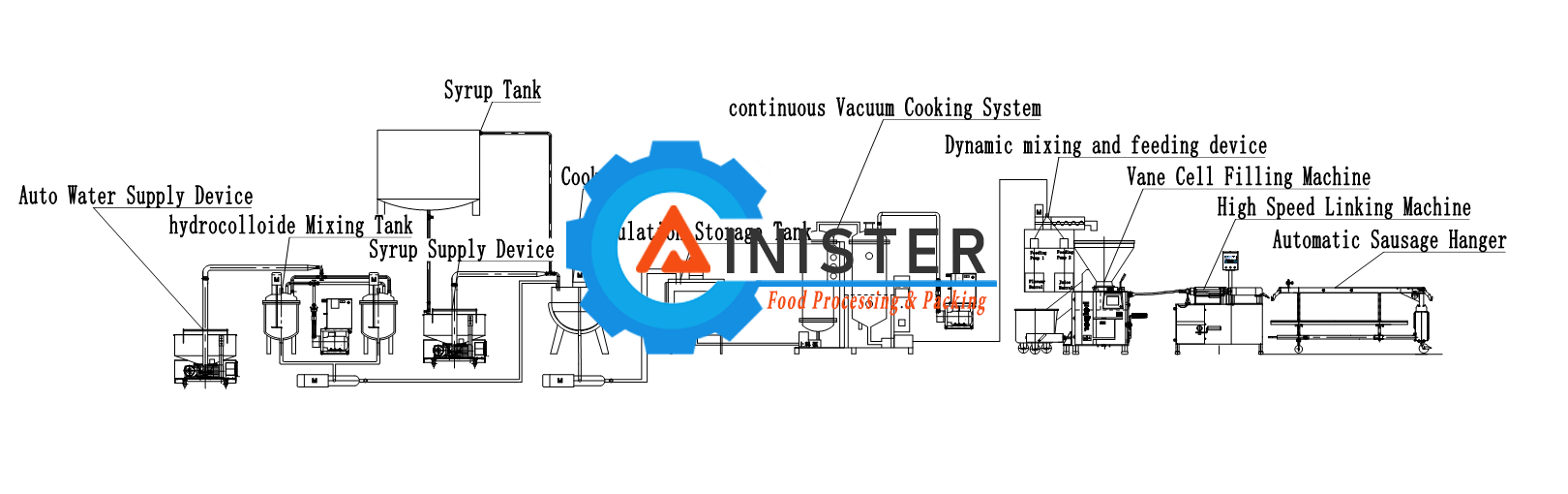

The juicy gummy that originated from Japan, which is characterized by adding a large amount of fruit juice during the sol process, while controlling and locking the water and juice of the gummy by boiling, and then filling it in the collagen casing. In this way, the original flavor of high-moisture content can be preserved to the greatest extent possible, and the perfect combination of fruit juice and soft candy can be maintained. After continuous improvement and customer feedback, we have made the production line more mature.

The cooking and mixing of raw materials adopt dynamic, automatic control, and precise temperature control. The tank body adopts a double-layer insulation structure to ensure that the materials are fully mixed and evenly mixed to achieve the most perfect taste. As a relatively fresh product, the processing technology requirements will be higher, and the ratio and mixing time of various materials need continuous experimentation and improvement.

Food-grade professional equipment is selected for filling and molding processing. Servo control, touch screen operation, simple and reliable, good product molding, fast speed, and the hanging system, greatly saving manpower and improving production efficiency.

The formed soft candy needs to be dried and humidified before proceeding to the next step. We use a drying furnace to achieve a series of functions such as drying, humidification, spraying, and exhaust at the same time. Using a touch human-machine interface, it can store nearly a hundred kinds of product formula data, which can be easily recalled. Rely on temperature and humidity sensors to achieve automation and precise control.

For twisted casing products, a cutting machine is needed to quickly cut the product. A multi-axis servo system, with PLC and a high-speed photoelectric sensor, can accurately locate the position of the candy granules. The special cutter design and separate cutting nodes ensure the integrity of the candy granules.At the same time, it can be adjusted according to the size of the product.

Since the casing is thin and the syrup is juicy, in order to prevent adhesion, but also to increase the gloss and taste, the juicy gummy also needs to go through an oiling process. The soft candy cut into granules is conveyed to the drum oiling machine via a conveyor. The atomizing nozzle equipped inside the drum can turn the viscous grease into an oil mist under high pressure, and spread it evenly on the surface of the sugar. The equipment adopts frequency converter for speed regulation and stepless speed regulation, which is suitable for different output and process requirements. The discharge end is connected to the conveyor belt and sent to the packaging machine to complete the packaging.

Specification and Technical Parameter

Product detail pictures:

Related Product Guide:

So as to provide you with ease and enlarge our business, we even have inspectors in QC Crew and guarantee you our best company and solution for Best-Selling Dog Food Production Machine - Juicy Gummy Production Line – Ainister , The product will supply to all over the world, such as: Las Vegas, Philippines, Egypt, Good quality and reasonable price have brought us stable customers and high reputation. Providing 'Quality Products, Excellent Service, Competitive Prices and Prompt Delivery', we are now looking forward to even greater cooperation with overseas customers based on mutual benefits. We will work whole-heartedly to improve our products and services. We also promise to work jointly with business partners to elevate our cooperation to a higher level and share success together. Warmly welcome you to visit our factory sincerely.

1.Do you provide goods or equipment, or solutions?

We do not produce final products, but are manufacturers of food processing equipment, and we also integrate and provide complete production lines for food processing plants.

2.What areas do your products and services involve?

As an integrator of the production line program of Helper Group, we not only provide various food processing equipment, such as: vacuum filling machine, chopping machine, automatic punching machine, automatic baking oven, vacuum mixer, vacuum tumbler, frozen meat/ Fresh meat grinder, noodle making machine, dumpling making machine, etc.

We also provide the following factory solutions, such as:

Sausage processing plants,noodle processing plants, dumpling plants, canned food processing plants, pet food processing plants, etc., involve a wide range of different food processing and production fields.

3.Which countries are your equipment exported to?

Our customers are all over the world, including the United States, Canada, Colombia, Germany, France, Turkey, South Korea, Singapore, Vietnam, Malaysia, Saudi Arabia, India, South Africa and more than 40 countries and regions, providing customized solutions for different customers.

4.How do you guarantee the installation and after-sales service of the equipment?

We have an experienced technical team and production workers, who can provide remote guidance, on-site installation and other services. The professional after-sales team can communicate remotely at the first time, and even on-site repairs.

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.