2018 High quality Meat Grinder - Freeze-Dried Pet Food Production Line – Ainister

2018 High quality Meat Grinder - Freeze-Dried Pet Food Production Line – Ainister Detail:

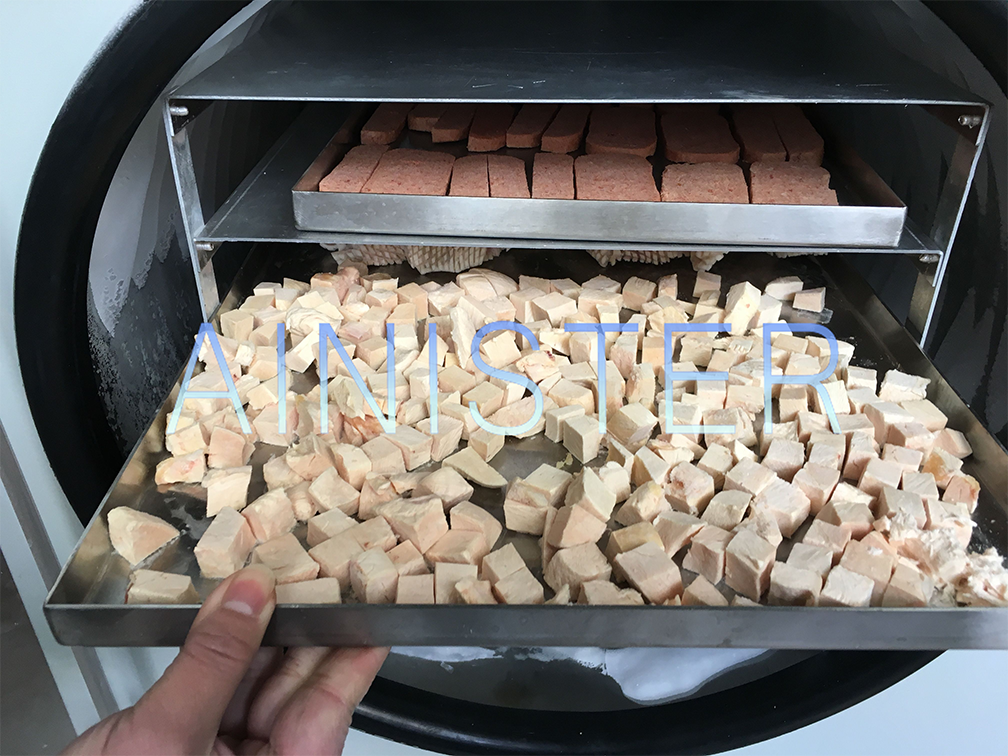

Freeze-dried food is the abbreviation of vacuum freeze-dried food. Its production process is to freeze-dry frozen meat, fruits, vegetables, and other food materials directly in a vacuum environment. The drying process of freeze-dried food is carried out at an ultra-low temperature, which takes about 24 hours. The ice crystal moisture inside will directly sublimate into gas, and will not undergo the process of melting into water. The moisture in the food is removed, and the nutrients inside are well retained. As the “fresh” in pet food, freeze-dried food is becoming more and more popular among pets.

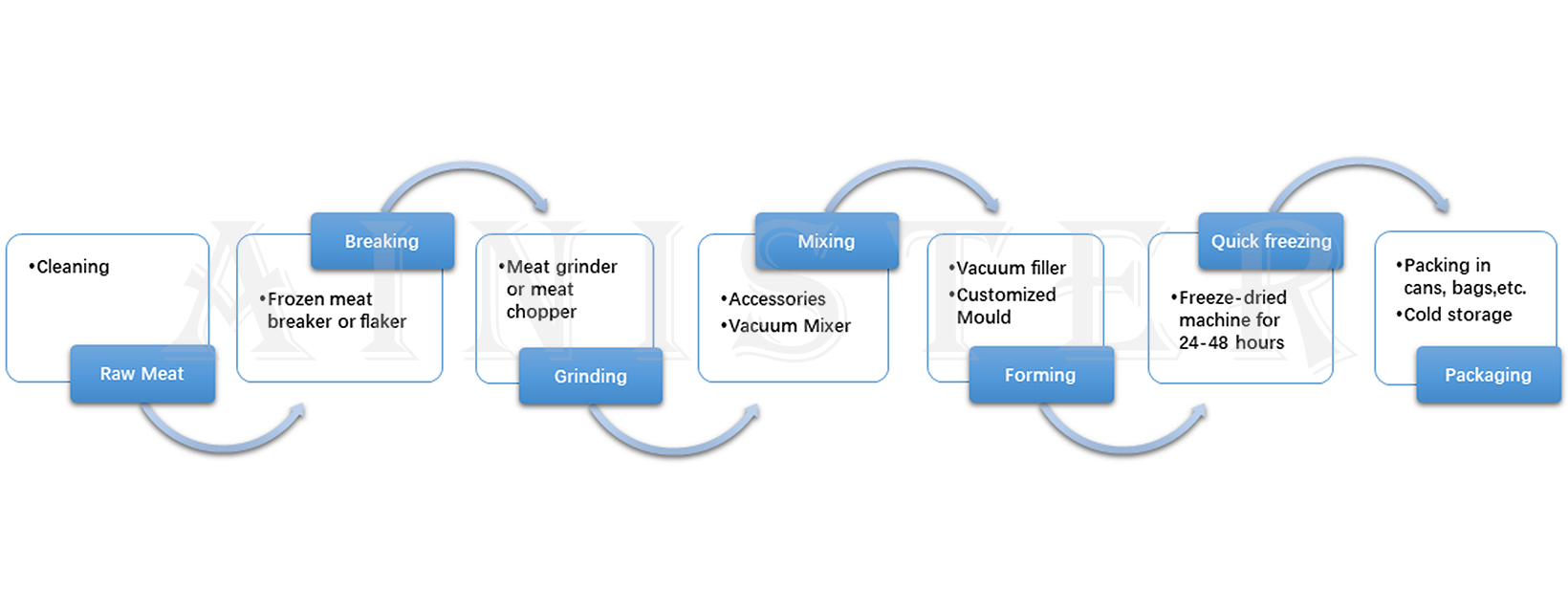

First of all, the meat needs to be selected and divided. Choose delicious and pure meat, and remove fat, corners, skin, and bones. Shape and cut into pieces without adding any other ingredients.Due to the different shapes and structures of meat, the cutting and sorting of raw materials generally need to be done manually.If you choose frozen meat as the raw material, you can use the frozen meat dicing machine series, equipped with inverter speed control, high-hardness knives, high output, fast speed and simple operation.

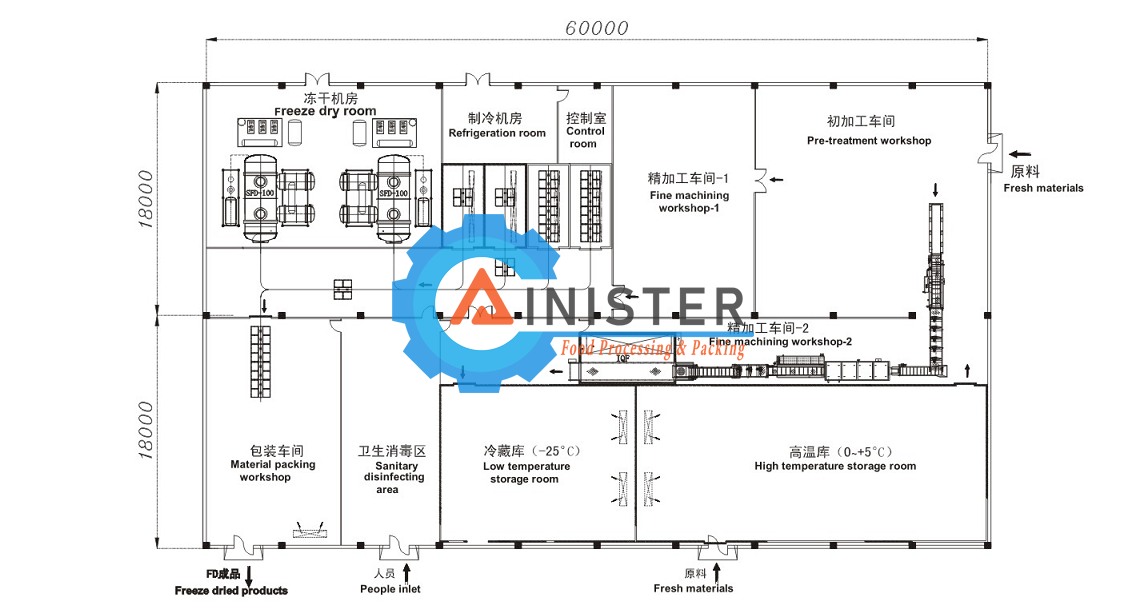

According to the demand for capacity and process, choose different freeze-drying equipment, for small production capacity, intermittent freeze-drying equipment can be selected, and for large-scale production and automation, continuous freeze-drying equipment can be selected. Coordinate the power supply, air pressure, and drainage energy assembly requirements to meet the production requirements.

Pre-freezing and drying are completed in situ, and the freeze-drying process is automated and easy to operate. The circulating medium runs inside the plate, the temperature can be adjusted, the temperature difference is ≤1℃, the cooling and heating effect is more uniform. Touch screen operation, PLC control system, real-time monitoring of equipment operation. It can be connected to a computer for remote control and storage of freeze-drying curves. The integral design is convenient for transportation and installation and saves space.

After the freeze-drying is completed, the finished product needs to be inspected after leaving the freeze-drying warehouse, and then bagged and packaged after passing the metal detector to ensure that it is safe.For automated production lines, a combination of multi-head weigher and bag-feeding packaging machine is a good choice. It can be accurately weighed and quickly packaged without tedious connection and operation.

Specification and Technical Parameter

- 1. Compressed Air:0.06 Mpa

- 2. Steam Pressure:0.06-0.08 Mpa

- 3. Power:3~380V/220V Or Customized according to different voltages.

- 4. Production Capacity:200kg-5000kg per hour.

- 5. Applicable Products: Freeze-dried chicken, freeze-dried beef, freeze-dried dog food, etc.

- 6. Warranty Period: One year

- 7. Quality Certification: ISO9001, CE, UL

Product detail pictures:

Related Product Guide:

We have now a hugely efficient team to deal with inquiries from buyers. Our goal is "100% client gratification by our solution high-quality, rate & our team service" and take pleasure in a great popularity among clients. With several factories, we will provide a wide assortment of 2018 High quality Meat Grinder - Freeze-Dried Pet Food Production Line – Ainister , The product will supply to all over the world, such as: Holland, Kuwait, Germany, If you need to have any of our merchandise, or have other items to be produced, make sure you send us your inquiries, samples or in depth drawings. Meanwhile, aiming to develop into an international enterprise group, we look forward to receiving offers for joint ventures and other cooperative projects.

1.Do you provide goods or equipment, or solutions?

We do not produce final products, but are manufacturers of food processing equipment, and we also integrate and provide complete production lines for food processing plants.

2.What areas do your products and services involve?

As an integrator of the production line program of Helper Group, we not only provide various food processing equipment, such as: vacuum filling machine, chopping machine, automatic punching machine, automatic baking oven, vacuum mixer, vacuum tumbler, frozen meat/ Fresh meat grinder, noodle making machine, dumpling making machine, etc.

We also provide the following factory solutions, such as:

Sausage processing plants,noodle processing plants, dumpling plants, canned food processing plants, pet food processing plants, etc., involve a wide range of different food processing and production fields.

3.Which countries are your equipment exported to?

Our customers are all over the world, including the United States, Canada, Colombia, Germany, France, Turkey, South Korea, Singapore, Vietnam, Malaysia, Saudi Arabia, India, South Africa and more than 40 countries and regions, providing customized solutions for different customers.

4.How do you guarantee the installation and after-sales service of the equipment?

We have an experienced technical team and production workers, who can provide remote guidance, on-site installation and other services. The professional after-sales team can communicate remotely at the first time, and even on-site repairs.

It is not easy to find such a professional and responsible provider in today's time. Hope that we can maintain long-term cooperation.